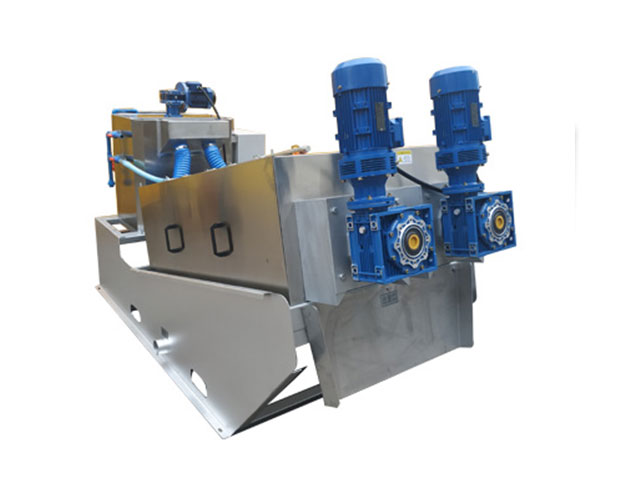

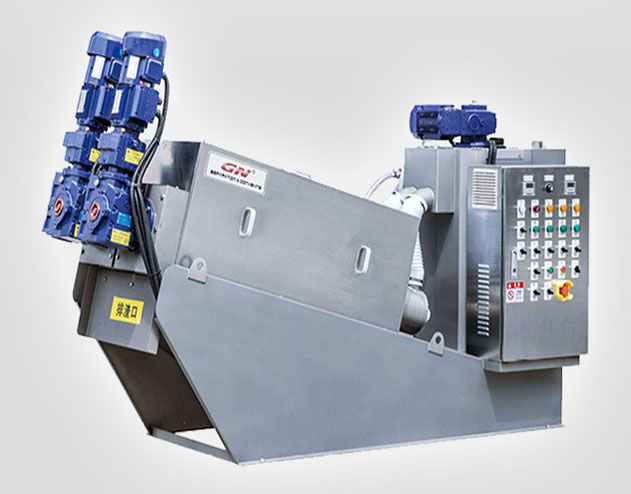

The screw press machine is a kind of economic and environmental friendly sludge dewatering equipment which uses the screw extrusion principle to realize the extrusion dehydration of sludge through the strong extrusion pressure generated by the change of screw diameter and pitch and the small gap between the swimming ring and the fixed ring.

| Model | DS Standard Capacity (Absolute Dry Sludge) | Capacity for Sludge with Dfiifferent Concentrat | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| GNDL101 | 5~7 kg/h | ~0.5m³/h | ~0.25m³/h | ~0.2m³/h | ~0.15m³/h | ~0.14m³/h |

| GNDL201 | 15~20 kg/h | ~1.5m³/h | ~0.75m³/h | ~0.6m³/h | ~0.5m³/h | ~0.4m³/h |

| GNDL202 | 30~40 kg/h | ~3m³/h | ~1.5m³/h | ~1.2m³/h | ~1m³/h | ~0.8m³/h |

| GNDL301 | 50~70 kg/h | ~5m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4m³/h |

| GNDL302 | 100~140 kg/h | ~10m³/h | ~5m³/h | ~4m³/h | ~3m³/h | ~2.8m³/h |

| GNDL303 | 150~210 kg/h | ~15m³/h | ~7.5m³/h | ~6m³/h | ~4.5m³/h | ~4.2m³/h |

| GNDL401 | 130~160 kg/h | ~13m³/h | ~6.5m³/h | ~5m³/h | ~4m³/h | ~3.2m³/h |

| GNDL402 | 260~320 kg/h | ~26m³/h | ~13m³/h | ~10m³/h | ~8m³/h | ~6.4m³/h |

| GNDL403 | 390~480 kg/h | ~39m³/h | ~19.5m³/h | ~15m³/h | ~12m³/h | ~9.6m³/h |

| GNDL404 | 520~640 kg/h | ~52m³/h | ~26m³/h | ~20m³/h | ~16m³/h | ~12.8m³/h |

| Model | Screw Diameter | Screw Qty | Screw Power | Agitator Power | Flushing Pressure | Flushing Water(L/H) | Weight(KG) |

| GNDL101 | 100mm | 1 | 0.18KW | 0.18KW | 0.1Mpa-0.2Mpa(No high pressure flushing device is required) | 24 | 220 |

| GNDL201 | 200mm | 1 | 0.37KW | 0.18KW | 32 | 420 | |

| GNDL202 | 2 | 0.74KW | 0.55KW | 64 | 550 | ||

| GNDL301 | 300mm | 1 | 0.75KW | 0.55KW | 40 | 900 | |

| GNDL302 | 2 | 1.5KW | 0.75KW | 80 | 1400 | ||

| GNDL303 | 3 | 2.25KW | 1.1KW | 120 | 1900 | ||

| GNDL401 | 400mm | 1 | 1.5KW | 1.1KW | 80 | 2200 | |

| GNDL402 | 2 | 3KW | 1.5KW | 160 | 3500 | ||

| GNDL403 | 3 | 4.5KW | 2x1.1KW | 240 | 5500 | ||

| GNDL404 | 4 | 6KW | 2x1.1KW | 320 | 6900 |

The screw press machine is a kind of economic and environmental friendly sludge dewatering equipment which uses the screw extrusion principle to realize the extrusion dehydration of sludge through the strong extrusion pressure generated by the change of screw diameter and pitch and the small gap between the swimming ring and the fixed ring.

The main body of the twin screw press machine is a filtering device formed by multiple fixed rings and swimming rings, and the spiral shaft runs through them. The front section is the concentration section and the rear section is the dehydration section, which completes the sludge concentration and pressing dehydration in one barrel, replacing the traditional filter cloth and centrifugal filtration mode with a unique and subtle filter body mode.

After gravity concentration in the concentration section, the sludge is transported to the dehydration section. In the process of moving forward, with the gradual reduction of filter joint and pitch and the blocking effect of back pressure plate, great internal pressure is generated and the volume is continuously reduced, so as to achieve the purpose of full dehydration.