1. Maximum output: 400 tons per day

2. Processing costs can be as low as US$50 per ton

3. Oil content of residue is lower than 0.1%

4. Wide range of applications, no geographical and seasonal restrictions

5. Recycling all the oil in the sludge and can generate additional income

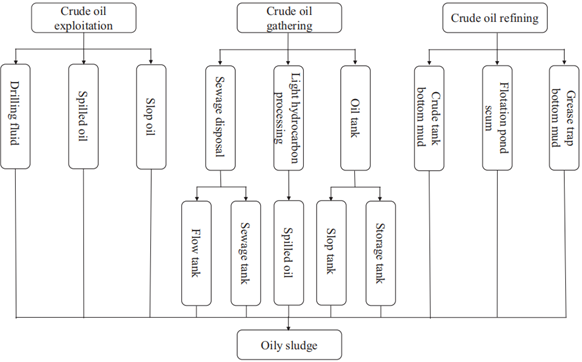

The petroleum production includes such procedures as exploration, installing, derrick, drilling, cementing, logging, seepage, drilling, gathering, refining ,transportation and storage of refined oil. Oily sludge is one of the most important pollution generated during these processes in petrochemical industry. The contained oil in oily sludge may be thought as the recovery resource, otherwise it is harmful to the environment. With the continuous exploitation of petroleum resources, and the accompanying excessive environmental contamination year by year, how to effectively treat oily sludge is the focus of worldwide attention. Thus, the treatment and reuse of oily sludge in oilfield industry has become a research hotspot in recent years.

The schematic diagram of the oily sludge source

Oily sludge is a mixture of crude oil or product oil mixed with soil or other media, in which the oil can not be directly recovered and may cause pollution. It is a hazardous waste and one of the main pollutants in petrochemical industry. The random disposal of oily waste not only wastes resources, but also pollutes soil and atmosphere. What’s more serious is the transfer and infiltration of petroleum hydrocarbons in soil, which pollutes groundwater and causes permanent ecological damage. After these harmful substances enter the water system or farmland, they are absorbed by plants passively and enter the human body through the food chain, causing various diseases and threatening human health.

The negative effects can be manifested in three aspects:

(1) The volatilization of petroleum components in oily sludge will lead to excessive concentration of total hydrocarbons in the air of surrounding areas;

(2) The improperly treated oily sludge will pollute the surface water, even the groundwater, and make the concentration of COD and petroleum substances in the water seriously exceed the standard;

(3) Oily sludge contains a large number of toxic and harmful organic compounds, such as hydrocarbons, phenols, anthracene and benzene ring compounds. Some substances have carcinogenic, teratogenic and mutagenic effects to the environment.

The physical and chemical properties of oily sludge are complex, so its treatment is a major problem in the petroleum industry. Based on this reason, the treatment technologies of oily sludge are introduced and analyzed. It is very difficult to treat oily sludge in oilfields. Most oilfields have not yet realized harmless and resource-based treatment. Generally, the method of stacking and drying after dehydration is adopted, which will not only occupy a large amount of land, but also cause pollution to air, water and solid. Enterprises also need to pay a large amount of sewage charges. It is necessary to further study the treatment technology of oily sludge in oilfields. With the improvement of national environmental protection requirements, oily sludge quality reduction, resource-based and harmless treatment technology will become the most potential technologies in the future.

| Comparison of common sludge disposal technologies | |||||

| No | Technology | By-products | Advantages | Disadvantages | Application |

|

1 |

Solvent extraction |

VOCs, Unrecoverable sludge slurry |

1)Easy to apply, fast and efficent; |

Large amout of organic solvents is used, high cost and not environmentally sound, unable to treat heavy metals |

Contain a large amount of refractory organic matter |

|

2 |

Chemical cleaning/Thermochemical treatment |

Wastewater |

1)Fast and efficent; |

High capital and maintenance cost, large energy consumption, noise problem, viscosity reducing pre-treatment requirment, unable to treat heavy metals |

Oily sludge with high oil content and light emulsification |

|

3 |

Centrifugation |

Wastewater, Unrecoverable sludge slurry |

1)Easy to apply, fast and efficent; |

High capital and maintenance cost, large energy consumption, noise problem, viscosity reducing pre-treatment requirment, unable to treat heavy metals |

Oily sludge with high oil content |

|

4 |

Flotation |

Large amount of wastewater |

1)Easy to apply; |

Relatively low efficiency, large amout of water is used, not suitable for treating oily sludge with high viscosity, unable to treat heavy metals |

Oily sludge with low viscosity |

|

5 |

Pyrolysis |

VOCs, Chars |

1)Fast and efficent; |

High capital maintenance, and operating cost, high consumption of energy, viscosity reducing pre-treatment requirment,and not suitable for oily sludge with high moisture content |

Oily sludge with low moist content and hard index |

|

6 |

Freezing/thawing |

Wastewater, Unrecoverable sludge slurry |

1)Easy to apply; |

Lower efficiency, cost could be high due to high energy consumption for freezing, unalbe to treat heavy metals |

Suitable for high-cold area |

|

7 |

Incineration |

Hazardous gas emissions, Fly ash |

1)Rapid and complete removal of PHCs in oily sludge; |

High equipment cost and auxiliary fuels, gas emissions and fly ash need further treatment, pre-treament moisture removal to required, unable to treat heavy metals |

Oily sludge with high oil content and low moist content |

|

8 |

Landfill |

Relatively small amount of VOCs |

1)Easy to apply; |

Can't be recycled, occupy a large amount of land, pollution to the environment, very slow process, waste resources |

Oily sludge with low oil content |

|

9 |

Biological treatment |

VOCs |

1)Easy to apply; |

Cann't be recycled, occupy a large amount of land, very slow process, limited application(temperature, humidity, complete cycle); |

Oily sludge with low oil content |

|

10 |

Combined processing |

Qualified discharge according to the Local environmental standards |

Wide application and djust process depend on the local sludge |

The equipment is complicated and the operation process is long |

Wide application and djust process depend on the local sludge |

Principles of oily sludge disposal:

Reduction, Harmless, Resource-based

Due to the diversity of oily sludge, there are great differences in the composition, physical properties and production of oily sludge. We are hard to disposal the oily sludge by a single technology and should combine with two treatments or more according to the report of sludge. We use combined processes and equipments on the basis of the corresponding to achieve the "good effect" and "benefit".

The treatment standard of oily sludge in oilfields usually depends on the use of the sludge after treatment. We can either use a certain technology alone or adopt a combined process of multiple technologies. It can not only achieve high treatment efficiency and good effect, but also reduce the overall disposal cost, maximize the resource recovery of "crude oil" in oily sludge, and greatly improve the economic benefits.

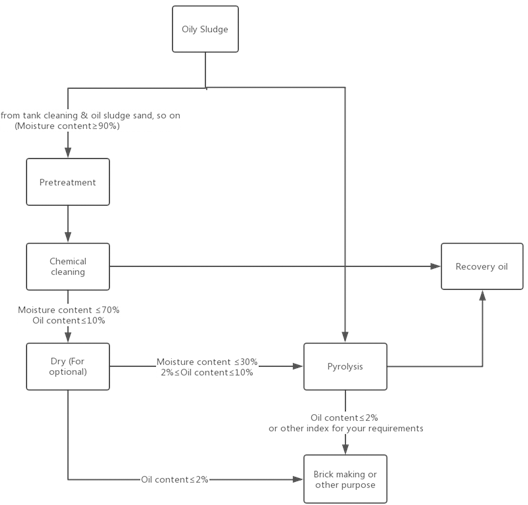

Flowchart of combined disposal technologies

The composition of oily sludge is more complex, and the oily sludge of each oilfield also has its own characteristics. According to the actual situation of oilfields, oily sludge is classified and treated in stages, And the treatment technology of oily sludge is diverse and has its own advantages. It is difficult to meet the environmental protection requirements by single treatment process, because no one technology can be used as an ideal method for treating all kinds of oily sludge. It is one of the development trends to combine various processes organically and strengthen the sludge deep treatment. With the improvement of various treatment technologies, the combined treatment measures such as mass adjustment centrifugal method and heat treatment method will be the main direction of sludge treatment.

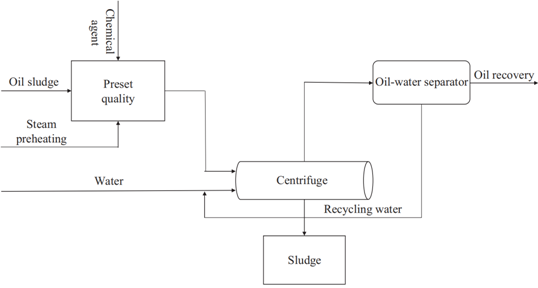

The main purpose of chemical cleaning technology also called thermochemical separation is to realize oil, sludge and water three-phase separation. The process is as follow: add an appropriate amount of hot water and chemical reagents into oily sludge, and change the properties of oil-liquid phase and oil- mud interface in oily sludge by the roll-up, emulsification, dissolution and solubilisation function of chemical reagents. As a result, crude oil is washed off from the surface of sludge, and the viscosity of oily sludge is reduced. Finally, the separation of oil, sludge and water is realized by the following settling and swirling processes.

The advantages of chemical cleaning method are simple, low cost, high reliability and high oil recovery rate. However, the chemical cleaning agent is easy to cause secondary pollution, and it has strong specificity. The different agents and addition ratio need to be selected according to different sludge. The separation efficiency of chemical cleaning method is affected by the type and dosage of reagent, washing temperature, liquid-solid ratio, stirring intensity, stirring time and pH value.

Flowchart of chemical cleaning system

(1) Auxiliary biosurfactant is much better than other alkaline cleaning agents in terms of oil removal effect, which can better infiltrate the surface and enhance the ability of microorganisms to degrade pollutants.

(2) The maximum treatment capacity of a single set of equipment can reach 200t/day, and the treatment cost is low.

(3) The whole set of equipment is be designed by skid mounted, which can realize integration and modularization, and the installation is fast and convenient.

(4) The purity of separated and recovered oil can reach more than 90%;

(5) The moisture content of separated discharged solid slag can be reduced to less than 70%;

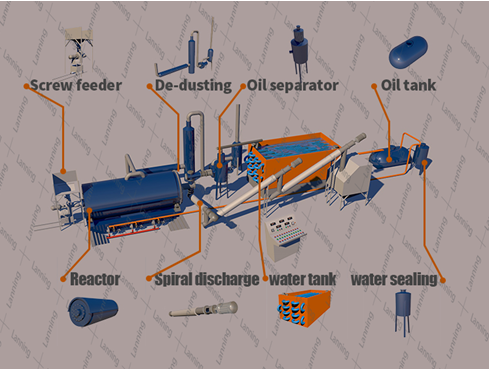

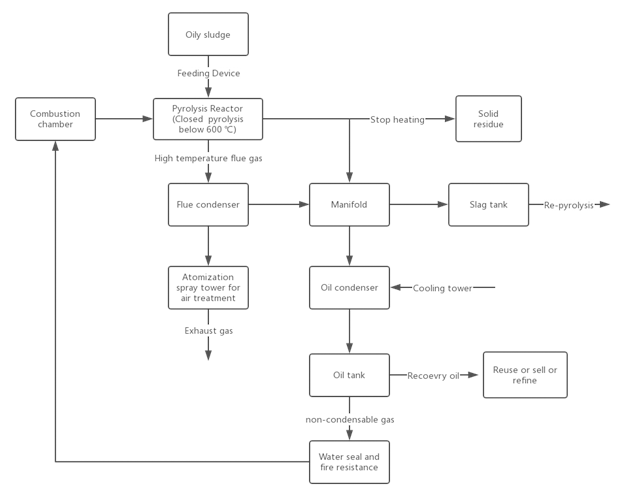

Pyrolysis system

Pyrolysis technology refers to the method of heating oily sludge under the condition of micro-positive pressure without oxygen, in order to separate out oil and organic matter, and segregate oily sludge into pyrolysis residue, pyrolysis liquid, and pyrolysis gas to achieve the purpose of resource utilization. The thermal transformation process of oily sludge can be divided into two stages: the first stage is called evaporation. When the temperature is below 350℃, light hydrocarbons with a low boiling point will evaporate from the oily sludge. The second stage is called parallel-sequential reaction. The pyrolysis reaction will happen on the heavy oil when the temperature exceeds 350℃, and hydrocarbons will generate free radicals due to thermal activation at about 400℃. Finally, oil, water, non-condensable gas and solid residue are produced. However, the proportion of things varies slightly when the reaction conditions changed.

Compared with the incineration method, the NOx and SOx discharged by the oily sludge pyrolysis process are far lower than the incineration process. Heavy metals and other pollutants in oily sludge can be enriched and fixed in solid residue, which greatly reduces the environmental pollution degree. The liquid product produced by pyrolysis process has good capacity reduction effect and is convenient for storage and transportation; the recovered oil can be directly applied to diesel engines; the solid residue can also be reused as material for brick making or oil field subgrade and so on. Thus, the pyrolysis method really realizes "turning waste into treasure" and recovers and utilizes the resources effectively.

(1) Dispose thoroughly, and the oil content of the treated residue can be lower than 0.3%;

(2) Oil can be recycled;

(3) The equipment of cost is low and has the advantages of small area, simple and convenient operation;

(4) It can realize closed feeding and discharging, micro negative pressure operation and no leakage of harmful gas,

(5) Non-condensable gas is directly applied to mini burner as fuel, improve resource utilization efficiency and reduce system operation cost;

(6) The rude oil burner which use the recovery oil as fuel for optional, improve resource utilization efficiency and reduce system operation cost;

(7) Do not add any agents in the processing process;

The production of oily sludge is an unavoidable problem in the process of petroleum development, and the harm of oily sludge to the environment is extremely serious. It will bring serious negative effects if it is not properly treated and disposed. Therefore, it is urgent to treat oily sludge properly. In the practical application of oily sludge disposal project, the company should select combined oily sludge disposal methods according to the characteristics of various disposal methods, combined with their own geographical location, crude oil types, process features, characteristics of oily sludge and enterprise demand. Single treatment technology cannot meet the requirements of environmental protection, while combined treatment technologies can meet the requirements efficiently. In the application of oily sludge treatment technology, attention should also be paid to the comprehensive consideration to the cost and the feasibility of the technology.

1) Solid Phase

a) Oil content of solid phase: 0.3%,

b) Moisture content of solid phase: 5-30% (Need to match solid drying system)

2)Recovered Oil

Moisture content of recovered oil: 2-3%

3)Water

a) Oil content of recycled water: 500-1000PPM (The recycled water can continue to be used for the machines)

b) Also discharge according to the local environmental standards